When you're deciding between pump options, it helps to see how they perform under pressure - not in the lab, but on actual job sites.

We’ve pulled together three different real-world uses of the Varisco ST-R self-priming trash pump. Different industries, different fluids - but one consistent lesson: good access makes hard jobs easier.

But first: What kind of pump is the Varisco ST-R - and is it right for you?

The Varisco ST-R is a self-priming centrifugal trash pump, purpose-built for handling dirty, abrasive, and solids-laden fluids. It belongs to a class of pumps designed to prime themselves without external systems, making them ideal for applications where suction lift is required, such as drawing from pits, tanks, or sumps.

ST-R Varisco Trash Pump Products

Key characteristics of the ST-R include:

- Self-priming up to 7.5 meters without a foot valve.

- Semi-open impeller that handles solids up to 76 mm in diameter.

- Front and rear access for fast maintenance and unclogging without removing pipework.

- Robust construction with options for cast iron, hardened iron, and stainless-lined internals.

So, is the Varisco ST-R Trash Pump right for your application?

Jump to learnings from the field >>

Here’s a quick checklist:

✅ Do you need to pump fluids with solids, rags, or abrasives?

The ST-R is designed for exactly that - think sewage, wastewater, slurry, or industrial wash water.

✅ Is downtime a concern?

Its design allows for in-field servicing, reducing the need for full disassembly or line isolation.

✅ Is your pump installed above the fluid level?

The ST-R’s self-priming ability makes it ideal for dry-mounted setups where suction lift is needed.

✅ Do you operate in tough environments - like recycling, agriculture, or treatment plants?

The ST-R thrives in these conditions, with corrosion-resistant options and rugged internals.

If your application involves challenging fluids, frequent clogging, or hard-to-access installations, the ST-R offers a practical, field-proven solution. It may not be the largest or most high-pressure pump in the Varisco lineup, but it’s often the most operator-friendly - and that can make all the difference.

What we learned from the field

1. Recycling plant: no shortcuts on abrasive fluids

Application: Transferring glue- and plastic-laden water from PET washing tanks.

Problem: Conventional pumps were wearing out too fast or struggling with priming when tanks were partially full.

.png?width=795&height=317&name=Varisco%20J-Series%20and%20ST-R%20Series%20Self-Priming%20Pumps%20are%20used%20widely%20in%20recycling%20plants%20around%20the%20world-%20(1).png)

Varisco J-Series and ST-R Series Self-Priming Pumps are used widely in recycling plants around the world.

What worked:

- The ST-R’s semi-open impeller and large solids passage handled the shredded debris well.

- Self-priming from below the tank simplified the pipe layout - no priming foot valve needed.

- When wear occurred, front and rear access made swapping parts possible in-situ.

Takeaway: For abrasive fluids, it’s not just about materials - it’s about how easily you can stay on top of wear.

2. Sewage pump station: clearing clogs without disruption

Application: Pumping untreated sewage with rags and fibrous solids.

Problem: Frequent clogging and long downtime during disassembly. The team needed something they could clear quickly - without isolating the pump line.

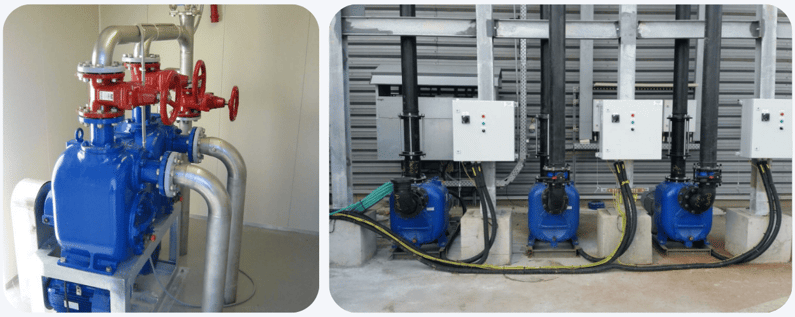

Varisco ST-R Self-priming trash pumps in use at a sewage treatment plant. Both the J-Series and ST-R are used widely in sewage treatment facilities.

What worked:

- The front inspection hatch allowed direct access to clear blockages without touching the pipework.

- Stainless-lined internals helped in corrosive areas.

- Surface-mount installation made it easier for operators to carry out checks.

Takeaway: If blockages are part of the job, make them easy to deal with.

3. Wastewater treatment: a reliable backup with low maintenance

Application: Supporting a heavy-duty line in a treatment plant.

Problem: The main pump (a larger J-Series) was effective but required more downtime for servicing.

.png?width=795&height=316&name=Varisco%20ST-R%20Self-priming%20trash%20pumps%20in%20use%20at%20a%20sewage%20treatment%20plant-%20Both%20the%20J-Series%20and%20ST-R%20are%20used%20widely%20in%20sewage%20treatment%20facilities-%20(1).png)

A Varisco ST-R Self-priming Trash Pump in use at a wastewater purification facility.

What worked:

- The ST-R was brought in as a lower-flow backup.

- Its rear pull-out design meant that even seal or shaft changes could be done without touching the motor or pipework.

Takeaway: Even as a secondary unit, serviceability reduces total plant downtime.

Across these three jobs, the standout feature wasn’t performance, it was access. The ST-R isn’t the biggest pump Varisco makes, but for challenging fluids or constrained sites, its design helps crews work faster, with less disruption.

That’s the bit that spec sheets don’t always show. That’s the bit that saves money in the long run.