Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

Wastewater Pumps

- Home

- Solutions

- Industrial

- Wastewater Pumps

Taking care of your wastewater

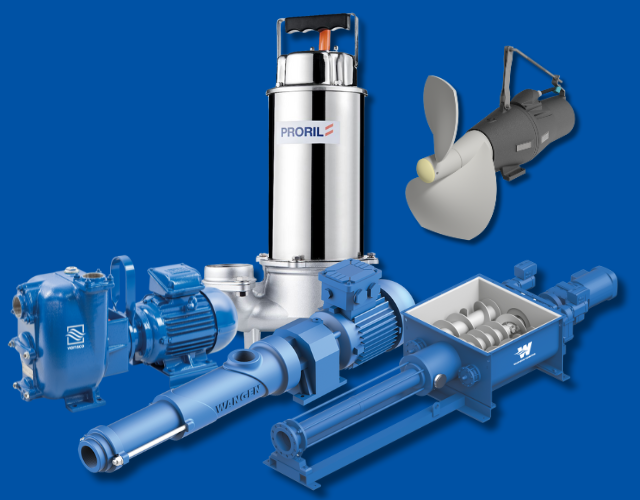

Industrial wastewater isn’t one-size-fits-all, and neither are the pumps that move it. Whether you’re designing a new plant or keeping existing systems running, you need wastewater pumps that handle the job efficiently—without clogging, failing, or slowing production.

We supply a diverse range of industrial wastewater pumps and stirrers designed to tackle everything from light process water to thick sludge and fibrous waste. With options including submersible and surface-mounted pumps, cutters, and stirrers, we’ll help you find the right fit for your plant.

Tailored pumping solutions

Our Industrial Team are industry-trained and offer in-depth knowledge of industrial pumps and systems. Choose from our extensive range of:

- Self-Priming Centrifugal pumps – High-flow solutions for process wastewater transfer.

- Diaphragm pumps – For abrasive or chemically aggressive wastewater.

- Submersible pumps – For wastewater pits, sumps, and direct tank installations.

- Progressive cavity pumps – Easily convey thick sludge and viscous waste.

- Stirrers – Keep solids in suspension.

Genuine parts & sound advice

We supply genuine parts for the pump brands we carry, with stock of common wear parts held locally in New Zealand. Our dedicated Industrial team works closely with supply partners to ensure we provide the right parts and expert advice.

- Genuine parts for reliability and performance

- Stock held in NZ for fast delivery

- Maintenance advice tailored to your needs

- Servicing on request to keep your equipment running smoothly

We’re committed to keeping your pumps in top condition.

.webp)

Overview of our Wastewater Pumps

Ideal for handling tough wastewater applications with high dry solids content, ensuring reliable and robust performance.

- Power: 1.5 to 18.5 kW

- Long service intervals

- Heavy-duty construction

- Strong, user-friendly mounting brackets

Designed for optimal wastewater treatment, preventing sedimentation and ensuring efficient media movement.

- Power: 1.5 to 18.5 kW

- Self-cleaning propeller

- Low energy consumption

- Heavy-duty cast structures

Designed for high flow, low pressure situations where transfer of thick slurries is required.

- Size: 50mm - 152mm

- Max Flow: 830L/min

- Max Head: 15m

- Max Solids: 60mm

Designed for high flow, low pressure situations where transfer of thick slurries is required.

- Size: 50mm - 102mm

- Max flow: 520L/min

- Max head: 15m

- Max Solids: 60mm

Wangen produces an extensive range of hopper feed pumps for slurries and pastes with high solids content (KL-R Series) and dewatered sludge (KL-RU, KL-RQ, KL-RS and KL-R Triplex models).

- Max flow: 160m3/hr

- Max pressure: 48 bar

- Max solids: 45%

- For extremely dry or lumpy material

- Max flow: 102m³/hr

- Max pressure: 6 Bar

- Max Dry Solids: 8%

- Compact and designed for hard to access locations

Corrosion-resistant, durable submersibles used to transfer clean or slightly contaminated water up to 40 degrees.

- Size: 50mm – 76mm (2”-3”)

- Max flow: 11L/s

- Max head: 20m

- Max solids: 40mm

Wangen's KL-S, KB-S and KB22S self-priming PC pumps convey high viscous media up to 200,000mPA-s with or without solids. The KB22S is designed specifically for dosing.

- Max Flow: 560 m3/hr

- Max Pressure: 48 bar

- Materials: S/steel, cast iron

The Hyline Series by Wangen features flexible and maintenance-free joints, and sedimentation-free design. Convey or dose food and beverages, cosmetics and pharmaceuticals.

- Max flow: 7m3/hr

- Max pressure: 20 bar

- Max solids: 26mm

The AM Series bronze, self-priming centrifugal pumps have a double volute body. Use for bilge, deckwash, fire prevention or ballast.

- Max flow: 100m3/hr

- Max head: 79m

Varisco J-Series pumps suit applications that require fast priming from demanding suction heights, and the ability to manage polluted, waste and abrasive fluids with suspended solids.

- Max flow: 1200m3/hr

- Max head: 110m

- Max solids: 76mm

- Self-priming 7.5m

SolidsPro stirrers are used to ensure uniform mixing in waste liquids with solids present, to prevent sedimentation and enhance biological or chemical reactions. Commonly used to agitate dairy effluent storage sumps/tanks & ponds to prevent solids from settling out.

- Cast AISI 316 S/Steel Propellor

- AISI 304 S/Steel mounting brackets

- Self-cleaning blades

- Double mechanical seal in oil bath

Engineered to resist clogging SolidsPro vortex submersibles feature recessed impellers with large free passage. Ideally suited to pumping large volumes of waste fluids where solids or particle are present.

- Max flow: 103m3/hr

- Max head: 20m

- Max solids: 80mm

- Humidity probe: yes

Wangen KL-T Series Progressive Cavity Immersion pumps safely convey media from tanks and pools with high metering accuracy even at low rpm.

- Max Flow: 102m3/hr

- Max Pressure: 6 bar

- Max viscosity: 200,000 mPA-s

- Max Dry Solids: 16%

Varisco J-Series pumps suit applications that require fast priming from demanding suction heights, and the ability to manage polluted, waste and abrasive fluids with suspended solids.

- Max flow: 1200m3/hr

- Max head: 110m

- Max solids: 76mm

- Self-priming 7.5m

Prime Fluid Management supplies genuine parts for our pump brands, holding stock of common wear parts in New Zealand.

- Genuine parts

- Stock held in NZ

- Maintenance advice

- Servicing on request

Questions? Specs? Talk to one of our Industrial Specialists today.

In the field

Here are some examples of our solutions being used.