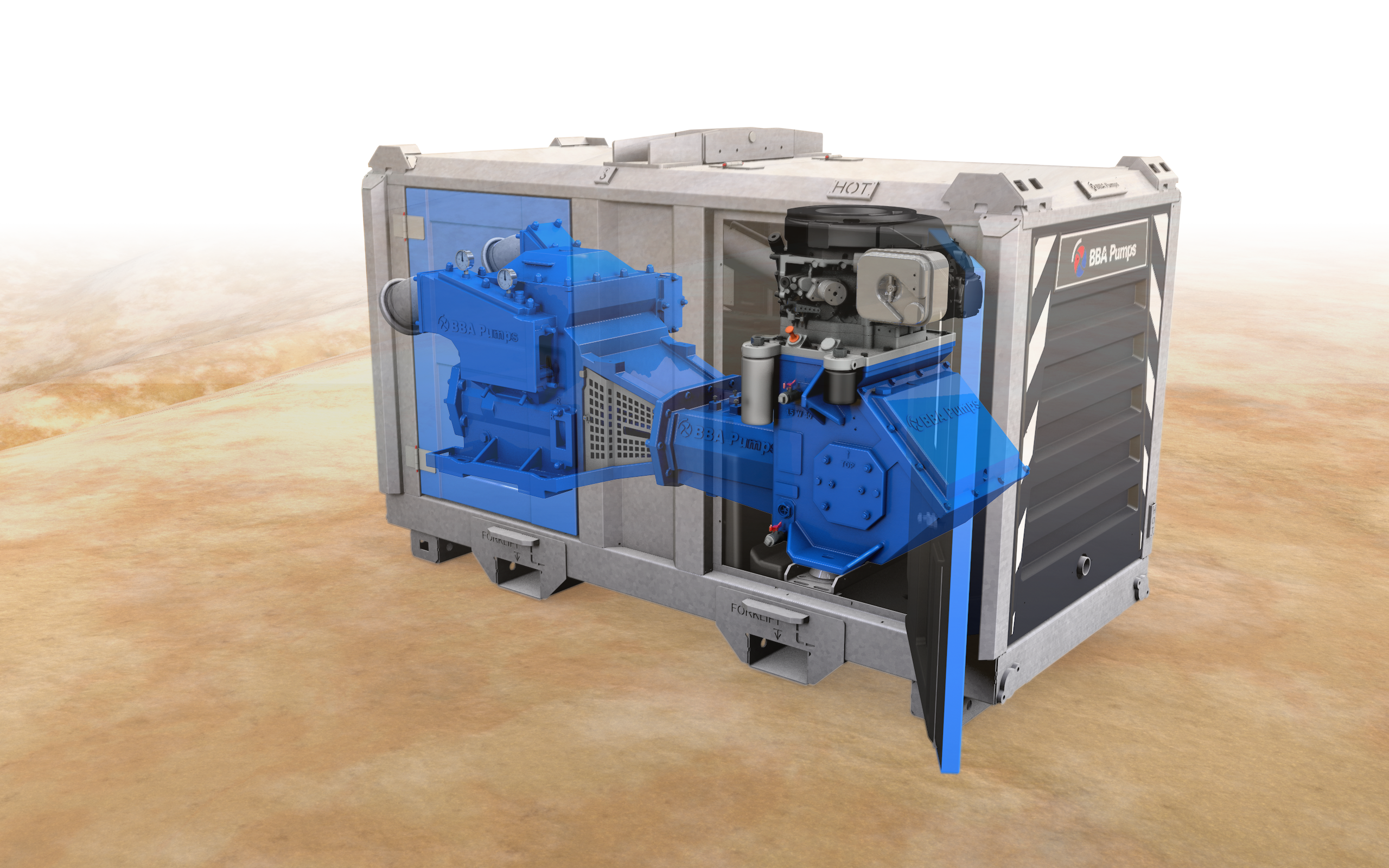

BBA introduced their ergonomic and performance-friendly DriveON® technology in 2023. The concept is worth revisiting because the PT DriveOn® technology continues to offer significant performance and handling improvements for wellpointing - in both the original 4-inch and newer 6-inch models.

The PT DriveOn® delivers 30 m³/h at a maximum head of 18mwc. This diesel-driven piston pump uses just 0.7 liters of fuel per hour and only requires servicing every 1,500 hours. That’s three times fewer maintenance intervals compared to the PT130, resulting in 66% less downtime and reduced consumable costs for oil and filters.

When BBA initially calculated its performance, they found that over a 30,000-hour operating life, the PT100 consumes 6,000 litres less fuel than its predecessor. With current fuel prices, this translates to substantial cost savings. Moreover, the reduced fuel consumption results in 15 tonnes less CO₂ emissions. Based on Q2 2023 European pricing, the financial saving over 30,000 hours was estimated at over $23,000.

Key improvements with the move to DriveOn® technology:

- 66% less maintenance – service intervals for the new pumps increased from 500 to 1,500 hours

- 6,000 liters of fuel saved – at 0.2 L/hr reduction across 30,000 hours

- 15 tones less CO₂ – fewer emissions from lower diesel use

- $23,000+ in cost savings – based on fuel, oil, filter, and labour costs over 30,000 hours run time

The figures above compared the PT100 DriveOn® with the PT130 it replaced.

Comparative Analysis of the PT150 Model vs. Competitor Dewatering Pump Over a 4950-Hour Operational Duration

| BBA PT150 | Competitor pump | |

| Service Intervals (Hrs) | 1500 | 250 |

| No. of services | 3.3 | 19.6 |

| Service Cost | $ 3,135 | $ 18,620 |

| Total Service Savings | 15,485 | |

| Fuel Usage ( L) | 1.2 | 2.1 |

| Total fuel used ( L) | 5,880 | 10,290 |

| CO2 Produced | 3.168 kg/hr | 5.544 kg/hr |

| Cost per liter at time of comparison | $2.00 | $2.00 |

| Total Fuel Cost | 11,760.00 | $20,580.00 |

| Total Fuel Cost | 11,760.00 | $20.580.00 |

| Total Fuel Savings | $8,820 |

Watch the video below to see how the ergonomic design improvements of the PT100 DriveOn® enhance maintenance efficiency and support employee well-being.

Do you know the operating expense of your pump fleet?

Whether you are planning a new project or reviewing your existing fleet costs, we work with you to identify potential fuel, maintenance, and emission savings.

Curious? Get in touch today for a no obligation chat.

BBA DriveOn® Well pointing Pumps are long-term cost-saving option. For more details, visit our Well pointing page on our website.

-2.png?width=300&name=Untitled%20design%20(2)-2.png)