Crest Pumps

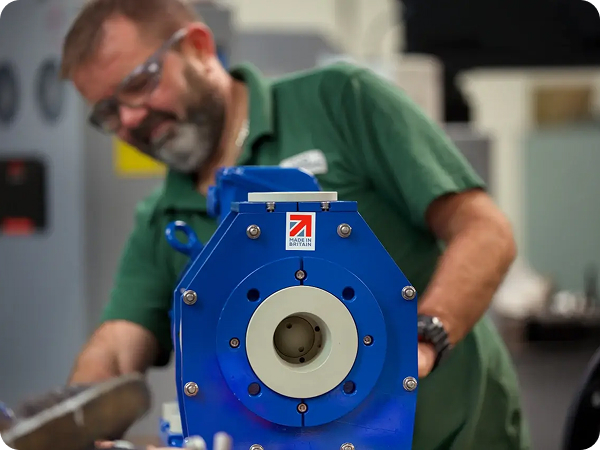

UK-manufactured Crest Pumps specialise in non-metallic chemical pumps to handle corrosive and hazardous substances.

Durable Engineering for Harsh Chemical Environments

Established in 1973, Crest Pumps manufactures corrosion resistant pumps from solid blocks of high-quality plastics. This UK-based producer builds mechanical seal pumps, seal-less chemical pumps, industrial chemical pumps, and chemical handling pumps to stand up to acids, alkalis, and aggressive fluids that destroy standard equipment.

Prime Fluid Management imports Crest Pumps directly from the manufacturer. Our technical team helps New Zealand industries select the right chemical transfer pumps and corrosion-resistant pumps for specific applications, backed by local parts inventory and servicing capability.

Why Choose Crest Pumps?

Prime Fluid Management maintains an established partnership with Crest Pumps. Their products combine engineering excellence with practical reliability across industrial environments.

Low Maintenance & Durability

Machined from solid plastic blocks, Crest Pumps resist corrosion better than fabricated alternatives. This construction delivers relatively low wear and extended service life.

No Obsolete Parts Policy

Crest pumps are used by some of the world’s largest manufacturers including Unilever, GlaxoSmithKline, BASF Chemicals and General Electric. A two-year warranty is standard, and Crest commits to providing replacement parts for pumps, no matter their age. This eliminates forced equipment replacement and protects long-term capital investment.

Authorised Parts & Support

At Prime Fluid Management, we ensure you have ongoing support to keep your chemical pumps running smoothly. From ready access to common wear parts to refurbishments, our team provides fast, efficient service.

Crest PP, ECC, EOV & PPM Series

Crest mechanical seal pumps handle chemical transfer, dosing and recirculation across industrial sectors. Machined from solid polypropylene, PVC or PVDF blocks, they deliver smooth, reliable flow for corrosive and hazardous liquids

Crest VSL, CSS & PPS Series

Crest vertical immersion pumps operate without mechanical seals on the wetted shaft. This patented run-dry design prevents damage during tank emptying or supply interruptions, making them ideal for chemical sump applications and corrosive liquid handling.

PP series mechanical seal pumps handle chemical transfer, recirculation and dosing across industrial applications. Built from solid polypropylene, PVC or PVDF blocks for maximum corrosion resistance.

- Max capacity: 26m³/h

- Max head: 22m

- Connections: 1" to 2"

- Materials: PP, PVC, PVDF, PTFE

- Semi-open impeller for solids handling

Enhanced versions of the PP range with improved efficiency. The EOV delivers up to 15% performance increase while consuming up to 20% less power compared to the ECC range.

- Advanced hydraulic design

- Energy-efficient operation

- PP, PVC, PVDF, PTFE construction

- Corrosion resistant for demanding applications

- Reduced lifecycle costs

Mechanically sealed multi-stage chemical pumps deliver higher pressures for applications requiring elevated heads. Corrosion resistant polypropylene construction for harsh chemical environments

- High-pressure chemical dosing

- Reverse osmosis applications

- Filter press operations

- Boiler feedwater (chemical plants)

- Multi-stage design for increased head

Low-maintenance VSL pumps feature a 400mm column and balanced impeller to prevent liquid backing up the pump shaft. Uses: metal treatment, tank emptying, transfer and re-circulation.

- Max capacity: 80m3/hr

- Max head: 40m

- Column length: up to 750mm

- Materials: Polypropylene, PVC, PVDF, 316 s/s

Rugged, totally corrosion-resistant pump. Cantilever shaft and patented run-dry design. Uses: sump emptying, recirculation, effluent treatment, flume scrubbers.

- Max capacity: 65m3/hr

- Max head: 40m

- Column length: up to 750mm

- Materials: Polypropylene, PVC, PVDF

Large-scale, reliable, heavy-duty pumps. Wetted parts are corrosion resistant. Machined from solid plastics.

- Max capacity: 250m3/hr

- Max head: 48m

- Column length: 1m – 4.5m

- Materials: Polypropylene, PVC, PVDF, 316 s/s

Prime Fluid Management supplies genuine parts for our pump brands, holding stock of common wear parts in New Zealand.

- Genuine parts

- Stock held in NZ

- Maintenance advice

- Servicing on request