Choosing the Right PC Pump: A Practical Comparison of Wangen and Mono (NOV) Technologies

Progressive cavity (PC) pumps are essential in industries requiring precise, low-pulsation fluid transfer. In New Zealand’s industrial sectors—ranging from wastewater and dairy to pulp and paper—PC pumps are valued for their ability to handle viscous, abrasive, and shear-sensitive media. This article provides a technical comparison of two leading PC pump manufacturers: Wangen, and Mono (NOV), with a focus on their engineering and operational advantages.

1. Mechanical Design and Load Handling

Wangen

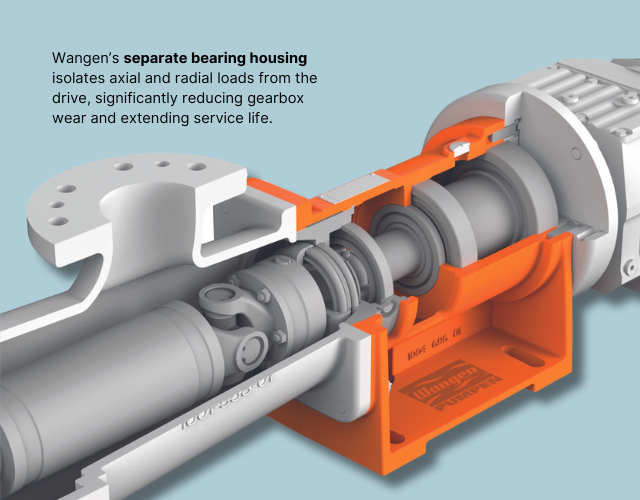

- Bearing Housing: Wangen integrates a separate bearing housing via a stub shaft & heavy-duty bearings between the pump and gearbox. This isolates axial and radial loads from the drive, significantly reducing gearbox wear and extending service life.

- No Baseplate Required: The bearing housing also eliminates the need for a baseplate, simplifying installation and alignment.

- Maintenance Advantage: The motor and gearbox can be removed without disturbing the pump or pipework, reducing downtime during servicing.

Mono

- Direct Mount: Pump mounts directly onto the gearbox shaft without intermediate bearing support. This places all thrust loads directly on the gearbox, increasing wear and maintenance frequency.

- Baseplate*: Often required for alignment and support.

2. Joint Technology

Wangen: Cardan Joint

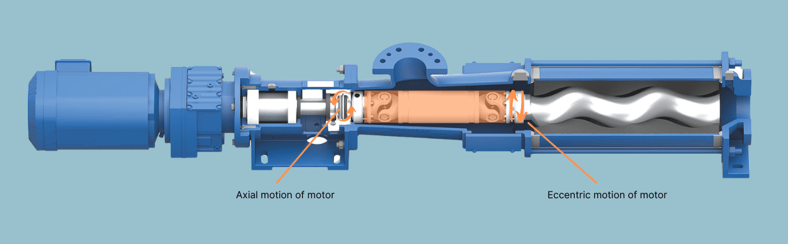

Wangen’s fully encapsulated cardan joint, equipped with needle roller bearings and a protective sleeve, is engineered for continuous, blockage-free operation in abrasive and fibrous media—minimizing wear and eliminating common failure points associated with conventional pin joints.

- Fully sleeved universal joint with needle roller bearings designed for long-term durability.

- High power transmission designed to maintain efficiency at high pressures.

- The joint easily handles radial and thrust loading.

Image: The cardan joint used in Wangen Progressive cavity pumps is designed to easily handle radial and thrust loading.

Mono: Pin Joint

Pin joints in progressive cavity pumps are prone to wear due to their design and constant mechanical stresses on a pin and bush, especially in abrasive or fibrous media. They often require frequent maintenance and are more susceptible to blockages and misalignment compared to encapsulated joint systems like Wangen’s cardan joint.

Summary of differences between a Cardan Joint and Pin Joint in progressive cavity pumps

|

Feature |

Cardan Joint |

Pin Joint |

|

Bearing Type |

Needle roller bearings with lifetime lubrication |

Not specified; generally, lacks advanced bearing systems |

|

Wear Resistance |

Easy load-handling minimises wear |

Fast wearing |

|

Flow Characteristics |

Constant diameter maintains flow velocity |

Diameter is not constant, increasing risk of sedimentation |

|

Fibre Handling |

Large diameter minimises fibre-wrapping |

Small diameter encourages fibre wrapping, leading to blockages |

3. Rotor and Stator Materials

Wangen

- Rotors: Hardened steel rotors for non-corrosive, abrasive applications. Superior to chrome-plated rotors, which can chip and degrade.

- Stators: Available in a wide range of elastomers (NBR, EPDM, FKM) for chemical compatibility.

Mono

- Rotors: Chrome-plated rotors are standard but prone to flaking, which causes damage to the stator.

- Stators: Comparable materials but rotor wear is a common issue in harsh environments.

4. Seal Technology

Wangen: LWD Cartridge Seal

The LWD Cartridge mechanical seal in Wangen progressive cavity pumps offers a compact, pre-assembled design that enables fast, tool-free replacement. It enhances reliability by minimizing leakage and wear, while reducing downtime and maintenance effort. This makes it a highly efficient and user-friendly sealing solution for demanding applications.

- Pre-assembled, oil-lubricated mechanical seal in a sealed chamber.

- Prevents ingress of solids and simplifies replacement.

- Simple replacement (a single piece).

- Ideal for abrasive applications.

Mono

Standard two-piece mechanical seals used in Mono (NOV) progressive cavity pumps are typically single or double seals housed in conventional seal chambers. These designs, while reliable, often require more disassembly and downtime for maintenance compared to cartridge-style systems and may not offer the same ease of access or modularity.

- Uses standard mechanical seals (prone to damage during assembly) or gland packing.

- EZstrip™ models improve access but still require more manual handling than Wangen’s cartridge system.

5. Operating Speed and Wear Rate

Operating speed has a significant impact on wear rate especially in abrasive applications. Studies show that doubling the RPM can increase wear by as much as 400%. Conversely, lower operation speed generates less heat and reduced vibration which leads to lower wear.

Wangen

- Pumps are designed to run at lower RPMs (typically 100–300 RPM but also at lower RPM where viscosity of the media requires).

Mono

- Often operate at higher speeds (up to 600 RPM) to achieve similar flow rates to Wangen progressive cavity pumps.

6. Availability and Support in New Zealand

Wangen has a growing presence in New Zealand with local distributors and service partners. Parts are stocked regionally, and technical support is available through trained agents. This ensures that industries using Wangen pumps have ready access to necessary components and expert assistance, minimizing downtime and maintaining operational efficiency.

Mono, on the other hand, has a strong distribution network across New Zealand, particularly in municipal and industrial sectors. Their established presence helps to ensure access to parts and support.

Summary of Features: Wangen and Mono (NOV) Progressive Cavity Pumps

|

Feature |

Wangen |

Mono (NOV) |

|

Bearing Housing |

Additional bearing housing reduces gearbox wear |

Direct mount (no bearing housing), increases gearbox wear |

|

Joint Technology |

Cardan joint, durable |

Pin joint, prone to wear |

|

Rotor Material |

Hardened steel, s/steel, hard chrome-plated |

Chrome-plated, s/steel |

|

Seal Technology |

LWD Cartridge Seal |

Standard mechanical seals or gland packing |

|

Operating Speed |

Lower RPM (100–300 RPM) |

Higher RPM (up to 600 RPM) |

|

Availability and Support |

Growing national presence |

Strong distribution network |

Engineering for Longevity and Efficiency

For New Zealand industries where abrasion, fibrous content, and maintenance costs are key concerns, Wangen PC pumps offer a technically superior solution.

Their robust mechanical design with bearing isolation, durable cardan joints, and hardened rotors contribute to extended wear life. Additionally, Wangen pumps are designed to run at lower RPMs, resulting in less heat, vibration, and wear. The quick-change cartridge seals further reduce downtime during maintenance, enhancing overall efficiency.

While Mono is a strong contender with a wide global footprint and innovative features, Wangen’s engineering-first approach and growing local support make it a compelling choice for demanding industrial applications.

Availability and Support in New Zealand

Selecting the right progressive cavity pump often involves more than just comparing specifications. At Prime Fluid, our in-house engineering team works closely with clients to ensure the chosen pump integrates effectively with existing systems and meets the demands of the application.

We can assist with:

- Duty-point selection and motor matching.

- Application-specific recommendations.

- Spare parts and servicing.

- Transition planning for legacy systems.

Genuine parts and service kits for Wangen pumps are stocked locally, helping reduce lead times and simplify maintenance planning.

If you're reviewing options for a new installation or planning to replace an existing unit, our engineers are available to help evaluate the best fit for your requirements.

Final thoughts

Both Wangen and Mono (NOV) offer reliable PC pumps for various industrial applications in New Zealand. The choice between them depends on specific operational needs and preferences.

Wangen's robust design, durable materials, and lower operating speeds make it a strong candidate for industries dealing with abrasive, viscous and fibrous media.

Mono's established presence and innovative features also provide solid performance. Ultimately, the technical comparison highlights the strengths of each manufacturer, allowing informed decision-making for optimal pump selection.