Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Agri Pumps

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Stormwater

Industrial

Chemicals

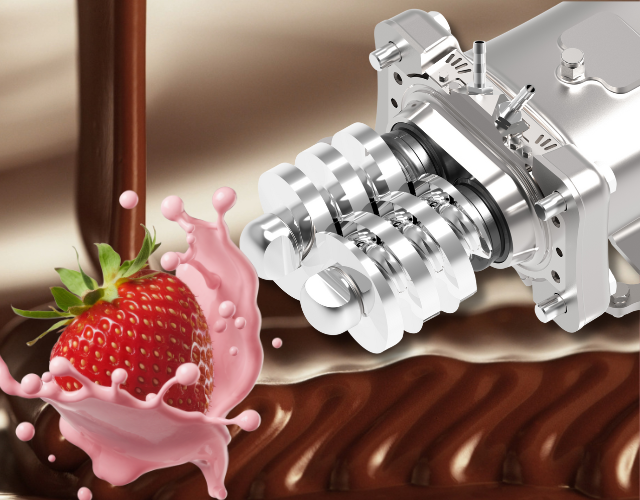

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Discharge Compliance

Comprehensive water treatment and monitoring solutions

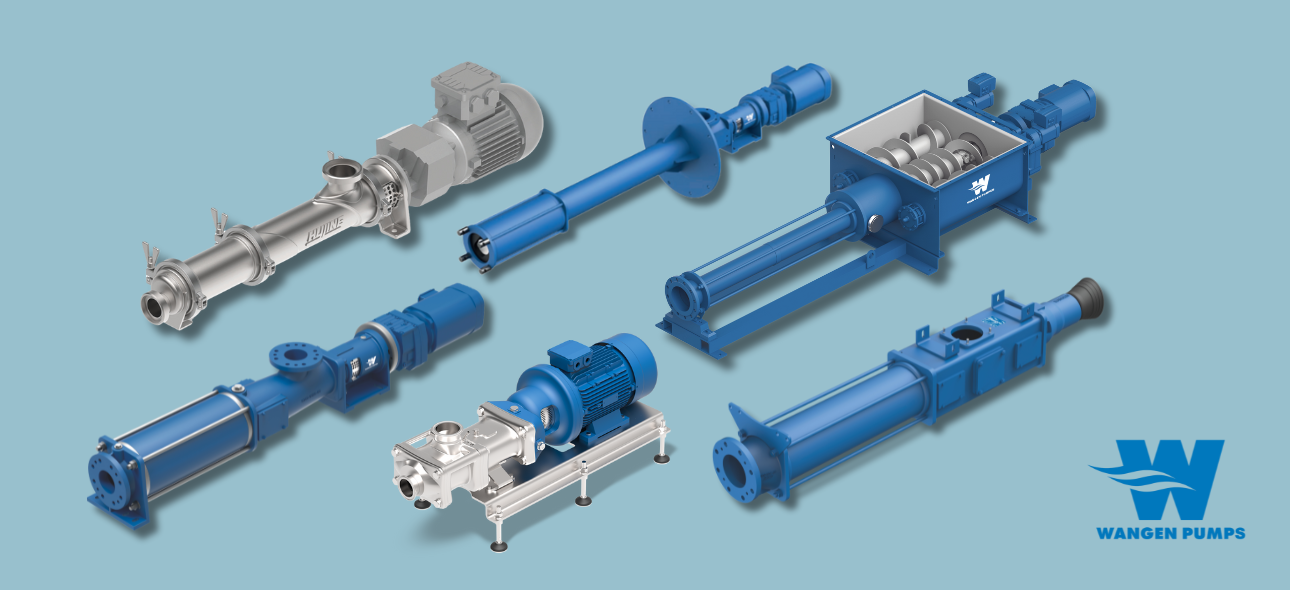

Wangen Pumps

Precision engineered for performance.

German Innovation. Local Expertise. Unmatched Reliability.

At Prime Fluid Management, we proudly supply Wangen Pumps, a global leader in progressive cavity pumps and twin screw pumps, engineered for the most demanding industrial and hygienic applications. Designed and manufactured in Germany since 1969, Wangen Pumps are renowned for their robust construction, low lifecycle costs, and exceptional reliability, even in the harshest environments.

Why choose Wangen Pumps?

- Engineered for efficiency: Wangen’s pumps deliver low-pulsation, continuous flow, independent of pressure or viscosity.

- Built to last: With wear-resistant components and patented quick-change systems like X-LIFT, Wangen pumps reduce downtime and maintenance costs.

- Hygienic by design: EHEDG and 3A-certified options ensure compliance in food, beverage, and pharmaceutical applications.

- Versatile applications: From effluent management to biogas, wastewater, and cosmetics, Wangen pumps handle everything from abrasive sludges to delicate creams.

Wangen in New Zealand

As the exclusive distributor of Wangen Pumps in New Zealand, Prime Fluid Management provides:

- Local technical support and servicing.

- Customised pump solutions for New Zealand’s unique industrial and agricultural needs.

- Expertise in solids handling, food-grade pumping, and biogas feed systems.

Whether you're managing effluent on a dairy farm, dosing additives in a food processing plant, or conveying high-viscosity sludge in a municipal facility, Wangen delivers performance you can trust.

WANGEN PUMP TECHNOLOGIES

Progressive Cavity Pumps

Ideal for viscous, abrasive, or shear-sensitive media, Wangen’s progressive cavity pumps are trusted across:

- Wastewater treatment sludge.

- Sludge handling and dewatering.

- Food and beverage processing.

- Agricultural slurry and manure transfer.

Models like the KL-SL, KL-RL, MX and Hyline offer modular flexibility, CIP/SIP compatibility, and minimal dead space for hygienic or industrial use.

WANGEN PUMP TECHNOLOGIES

Twin Screw Pumps

The Wangen Twin NG series is a game-changer for sanitary applications, offering:

- Gentle, pulsation-free pumping of volatile or gaseous products.

- Fast-X-Change® spindle replacement without re-synchronisation.

- EHEDG and 3A certifications for dairy, beverage, and cosmetic industries.

VIEW MORE SOLUTIONS

Explore Wangen Pump Solutions

Let’s Talk Pumping Performance

Need help selecting the right Wangen pump for your application? Contact us for expert advice, product specs, or a site assessment.

Overview of our Wangen Pumps

This pump is designed for precise conveying and dosing in wastewater treatment plants. It features a durable, wear-resistant flexible joint that requires no oil filling, ensuring maintenance-free operation and preventing media contamination

- Series: KB10 (Plastic)

- Flow Rate: 0.5 up to 200 l/h

- Series: KB22S (Cast Iron)

- Flow Rate: 200 up to 4000 l/m

- Max Pressure: 16 bar

Developed for ease of maintenance, you can change wear parts of the Wangen Xpress with the pump still in your pipeline. Suitable for low-viscous media.

- Series: Xpress

- Power: 7.5 – 18.5kW

- Speed: 152 – 221rpm

- Max flow: 102m³/hr

- Max pressure: 6 Bar

Wangen produces an extensive range of hopper feed pumps for slurries and pastes with high solids content (KL-R Series) and dewatered sludge (KL-RU, KL-RQ, KL-RS and KL-R Triplex models).

- Max flow: 160m3/hr

- Max pressure: 48 bar

- Max solids: 45%

- For extremely dry or lumpy material

Very low maintenance and highly dependable, Wangen KL Series of effluent PC pumps perform at very low rpm and features a unique, encapsulated cardon joint that is wear and maintenance-free.

- Power: 7.5 – 18.5kW

- Speed: 152 – 260 rpm

- Max flow: 60m³/hr

- Max pressure: 12 bar

- Max flow: 102m³/hr

- Max pressure: 6 Bar

- Max Dry Solids: 8%

- Compact and designed for hard to access locations

Wangen's KL-S, KB-S and KB22S self-priming PC pumps convey high viscous media up to 200,000mPA-s with or without solids. The KB22S is designed specifically for dosing.

- Max Flow: 560 m3/hr

- Max Pressure: 48 bar

- Materials: S/steel, cast iron

The Hyline Series by Wangen features flexible and maintenance-free joints, and sedimentation-free design. Convey or dose food and beverages, cosmetics and pharmaceuticals.

- Max flow: 7m3/hr

- Max pressure: 20 bar

- Max solids: 26mm

Wangen’s KB-SL, KL-SL and KL-RF hygienic progressive cavity pumps are tailored to convey low to very high viscosity media.

- Max flow: 150m3/hr

- Max temp.: 140°C

- Max pressure: 48 bar

- Max viscosity: 200,000 mPa-s

Available as a mobile or stationery unit, the MX-series hygienic progressive cavity pump offers differential pressure up to 80 bar.

- Max flow: 100m3/hr

- Max pressure: 80 bar

- CIP/SIP cleaning possible