Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

Wangen Progressive Cavity Pumps

Engineering Brilliance

For New Zealand industries where abrasion, fibrous content, and maintenance costs are key concerns, Wangen Progressive Cavity (PC) pumps offer a economically and technically superior solution.

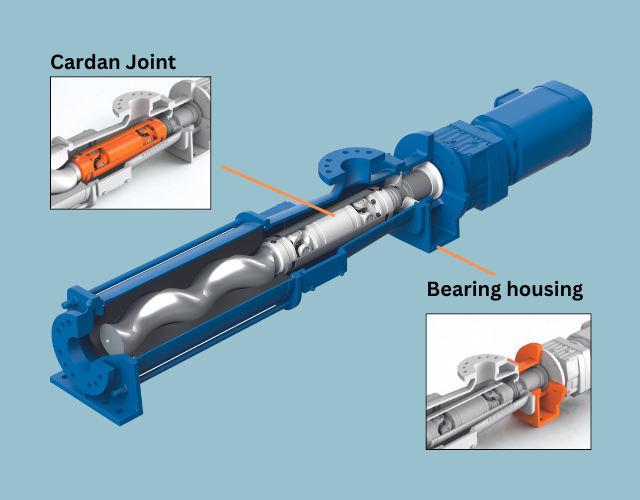

Their robust mechanical design with bearing isolation, durable cardan joints, and hardened rotors contribute to exceptional wear life. Wangen PC pumps also run at lower RPMs, resulting in less heat, vibration, and ultimately, wear. The quick-change cartridge seals further reduce downtime during maintenance, enhancing overall efficiency.

Blockage-free operation

Wangen’s fully encapsulated cardan joint has needle roller bearings and a protective sleeve. It is engineered for continuous, blockage-free operation in abrasive and fibrous media - minimising wear and eliminating common failure points associated with conventional pin joints. Wangen has also integrated a separate bearing housing between the pump and gearbox to isolate axial and radial loads from the drive, again, significantly reducing wear and extending service life.

- Fully sleeved universal joint with needle roller bearings designed for long-term durability

- High power transmission designed to maintain efficiency at high pressures.

- The joint easily handles radial and thrust loading.

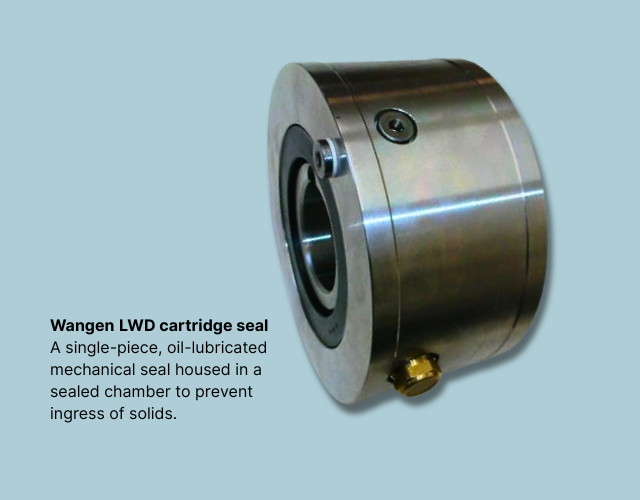

Maintenance-free Mechanical Seal

Wangen's LWD Cartridge mechanical seal offers a compact, pre-assembled design that enables fast, tool-free replacement. Pump reliability is improved and downtime reduced due to minimal leakage and wear. The net result is a highly efficient and user-friendly sealing solution, ideal for demanding applications .

- Pre-assembled, oil-lubricated mechanical seal in a sealed chamber.

- Prevents ingress of solids and simplifies replacement.

- Simple replacement (a single piece).

- Ideal for abrasive applications.

Overview of our Wangen Progressive Cavity Pumps

Wangen produces an extensive range of hopper feed pumps for slurries and pastes with high solids content (KL-R Series) and dewatered sludge (KL-RU, KL-RQ, KL-RS and KL-R Triplex models).

- Max flow: 160m3/hr

- Max pressure: 48 bar

- Max solids: 45%

- For extremely dry or lumpy material

Very low maintenance and highly dependable, Wangen KL Series of effluent PC pumps perform at very low rpm and features a unique, encapsulated cardon joint that is wear and maintenance-free.

- Power: 7.5 – 18.5kW

- Speed: 152 – 260 rpm

- Max flow: 60m³/hr

- Max pressure: 12 bar

Wangen's KL-S, KB-S and KB22S self-priming PC pumps convey high viscous media up to 200,000mPA-s with or without solids. The KB22S is designed specifically for dosing.

- Max Flow: 560 m3/hr

- Max Pressure: 48 bar

- Materials: S/steel, cast iron

Wangen’s KB-SL, KL-SL and KL-RF hygienic progressive cavity pumps are tailored to convey low to very high viscosity media.

- Max flow: 150m3/hr

- Max temp.: 140°C

- Max pressure: 48 bar

- Max viscosity: 200,000 mPa-s

Available as a mobile or stationery unit, the MX-series hygienic progressive cavity pump offers differential pressure up to 80 bar.

- Max flow: 100m3/hr

- Max pressure: 80 bar

- CIP/SIP cleaning possible

Wangen KL-T Series Progressive Cavity Immersion pumps safely convey media from tanks and pools with high metering accuracy even at low rpm.

- Max Flow: 102m3/hr

- Max Pressure: 6 bar

- Max viscosity: 200,000 mPA-s

- Max Dry Solids: 16%

KL-RL series progressive cavity pumps ensure nearly pulsation-free flow with a large hopper and screw conveyors to optimise pumping of non flowable product.

- Max flow: 65m3/hr

- Max pressure: 48

- Max solids: 95mm

The KL-RF hopper feed series is available in S-, L-, and H- rotor/stator geometries and is well-suited to plasticising blocks of fat or butter.

- Max flow: 22m3/hr

- Max pressure: 48

- Max solids: 95mm

Designed for agricultural use, Wangen’s PTO shaft pumps vacuum-load, unload and distribute tank manure supplies, or convey liquid feed.

- High suction power

- Insensitive to foreign bodies

- Max flow: 470m3/hr

- Max pressure: 16 Bar

In the field

Here are some examples of our solutions being used.

Read Dewatering, Bypass & Sewage articles

See other Dewatering, Bypass & Sewage Pumps

Make an enquiry

FAQ

At Prime Fluid Management, we understand that every fluid management challenge brings unique considerations. Here, you’ll find clear, practical answers and expert guidance to help you maximise uptime, achieve regulatory compliance, extend equipment life, and implement the most effective solution for your site.

On a lot of drawings and pump schedules, dry-prime pump or dry-prime dewatering pump is used as shorthand for a surface pump that can handle air and doesn’t need manual priming. In practice, the auto-prime units that Prime Fluid supplies are vacuum-assisted pumps with a dedicated priming system, so they meet the intent of most “dry prime” specs while giving you a modern, quieter and more efficient package.

Auto-prime units are usually the better option when the pump has to sit above the water, suction conditions might change, or you expect a lot of air to enter the line during setup and operation. A self-priming dewatering pump or submersible can still be the right choice on simpler, more static jobs, and Prime can talk you through which option will be more reliable and cost-effective for your site.

Yes – Prime can supply auto-prime packages as diesel dewatering pump sets or electric sets, depending on what power you have available and how the system will run. With the right control panel and level sensors, those same units can be configured as an automated pump or “auto water pump” that starts and stops itself, which is helpful on remote or 24/7 sites where you don’t want someone constantly watching the pump.

Auto-prime units are a good fit for temporary flood control pumps because they can be moved quickly, cope with long suction and discharge lines, and re-prime themselves as water levels change. Prime Fluid can set up high-flow Auto-prime Pump solutions for New Zealand councils and contractors that form part of a wider flood or stormwater contingency plan.

To match an Auto-Prime Pump New Zealand job, one of our sales engineers will usually ask for your required flow, total dynamic head, suction depth, discharge route, expected solids size and how long the pump needs to run. If your documents mention terms like autoprime dewatering pumps, auto vacuum pump or use a generic “dry prime” note, sending those details through with a simple sketch of the setup helps the team recommend the most suitable package for your project.