Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

Dredge pumps

Better for your bottom line.

Built for extreme environments

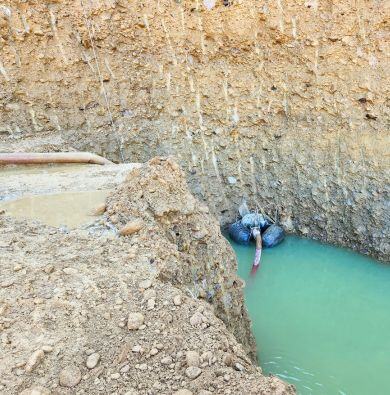

Dragflow dredge pumps and mini dredges deal efficiently to large volumes of sediment-laden water. They are well-suited to reclamation and coastal protection work, and pond and channel cleaning.

Key features include:

- High efficiency agitator, reversible and high chrome for long life and continuous flow lifting of deposited sediments.

- Low rotation speed: reduced wear and long-term efficiency.

- Rugged and heavy-duty construction: highly resistant components for loaded and abrasive mixes.

.webp)

The cost of poor performance

Efficient slurry and sludge management solutions will significantly improve your bottom line, with ‘hidden’ savings helping the systems to pay for themselves:

- Reduced power consumption

- Fewer breakdowns, lower maintenance requirement

- Less staff and equipment required to deliver the same or better solution

- Improved monitoring and reporting

Overview of our Dredge Pumps

Maximise versatility and effectiveness with Dragflow's small but mighty mini dredges.

Remote-controlled, easy to transport, easy to assemble.

These electric dredge pumps are often used for extracting material below the water table, or maintaining sludge levels.

- Size: 75mm – 300mm (3”-12”)

- Max flow: 833 L/s

- Max head: 120m

- Max Solids: 120mm

Designed to handle heavy slurries, primarily used for sludge transfer. Capable of pumping up to 70% of solids by wieght.

- Size: 100mm – 355mm (4”-14”)

- Max flow: 1,111 L/s

- Max head: 68m

- Max Solids: 120mm

Agitate compact sludge and other materials with powerful water jets.

- Electric & hydraulic models

- Filter & non-return valve

- Delivery line

Combined with the dredge pump’s agitator, these excavators break compacted material so that it can be drawn into the pump and discharged

- Replacable teeth

- Electric & hydraulic models

View our full range of dredge pumps and dredges

In the field

Here are some examples of our solutions being used.