Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

Sludge & Slurry Submersible Pumps

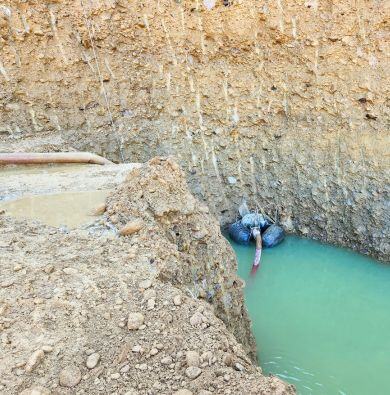

Your pit dewatering could do better.

Sludge and slurry submersible pumps are specialised pumps built to withstand highly abrasive fluids. They are constructed from hard metals and abrasion-resistant linings, with added features to prevent obstruction, overheating, and excessive wear.

These pumps are ideal for moving thick, solid-laden liquids such as wastewater and sludge from ponds, tanks, or treatment facilities. Whether you're managing water transfer on a construction site, cleaning out a sediment-filled pond, or handling industrial wastewater, submersible sludge pumps offer a reliable and portable solution.

Avalible for both hire and sale across New Zealand, these pumps are commonly used for dewatering, desludging, and transferring heavy liquids where durability and efficiency are critical.

.png)

Identify your performance drains

You know your quarry. We know our products. Together, we can identify performance drains and problem products that are hindering maximum productivity.At Prime Fluid Management, productivity assessments are a first step in our solutions pathway.

Working smarter

At Prime Fluid management we are look for technological advances in our products – design, engineering and connectivity features that will help you to:- Optimise resource

- Minimise handling and movement

- Improve operational safety

- Meet discharge and environmental obligations

- Reduce extraction costs

Overview of our Sludge & Slurry Submersible Pumps | NZ

The Solid, Salvador, Senior and Sandy models, designed for continuous, unattended operation where reliability is critical and solids content is high.

- Size: 50mm – 100mm (2” – 4”)

- Max flow: 24L/s

- Max head: 38mwc

- Max solids: 80mm

Constructed for maximum wear-resistance, the Grindex Bravo range handles highly abrasive liquids with a pH tolerance of 5.5 – 14. Agitators are built-in in some models.

- Size: 100mm – 150mm (4” – 6”)

- Max flow: 130L/s

- Max head: 45mwc

- Max solids: 40 mm

A rugged and cost-effective solution the Proril Stormy series feature high chrome impellers, agitators and wear plates to withstand tough slurry transportation.

- Size: 75mm – 200mm (3” – 8”)

- Max flow: 110L/s

- Max head: 30mwc

- Max solids: 40mm

- Size: 75mm – 300mm (3”-12”)

- Max flow: 50,000 L/min

- Max head: 120m

- Solids: 120mm

Suited to high head and heavy dewatering, dam or pond cleaning, extraction and coastal protection.

Significant economy over traditional methods.

- Size: 100mm – 350mm (4”-14”)

- Max flow: 66,700 L/min

- Max head: 68m

- Solids: 120mm

Constructed from AISI 316 stainless steel.

- Size: 2” – 6”

- Max flow: 130L/s

- Max head: 200m

- Solids: 80mm

Contact areas are constructed from 304 or 316 stainless steel.

- Size: 2” (50mm)

- Max flow: 43m3/h

- Max head: 18mwc

- Solids: 40mm

View our sludge and slurry pump range

See other Industrial Pumps

Read Industrial Articles

In the field

Here are some examples of our solutions being used.

They brought their mechanics, they didn't just dump it and leave….couldn't have done it without them to be honest

This sort of unique system you set up is what sets you apart from others in the Market

I had an amazing experience with Prime Pump at the Transmission Gully ... will recommend you guys anytime and anywhere.

You guys had our backs from the get-go and stood beside us and persevered.

We called for a different type of solution…... We were pretty happy with what's been delivered

Prime supplied us with the best solution for hire and the instant availability was what we needed… We certainly will be using them in the future

Make an enquiry

FAQ

At Prime Fluid Management, we understand that every fluid management challenge brings unique considerations. Here, you’ll find clear, practical answers and expert guidance to help you maximise uptime, achieve regulatory compliance, extend equipment life, and implement the most effective solution for your site.

It depends on the fluid, temperature, viscosity, and how the tank and pipework are laid out. A flooded suction setup is usually the most stable option for consistent performance, especially with higher viscosity oils, because the pump is always supplied with product.

If the pump needs to draw from a lower level or from a longer suction line, suction lift and self priming capability become important. However, the setup needs to be sized correctly to avoid issues like poor priming, air ingress, or cavitation. If you share your suction conditions and duty point, we can recommend a pump type and configuration that suits the installation.

For fuel and oil applications, reliability often comes down to protecting the pump from pressure spikes and contamination, and selecting the right sealing arrangement. Depending on the pump type and duty, options can include an internal relief or bypass valve to protect against dead heading, and an inline suction strainer to reduce the risk of damage from debris.

Seal selection also matters for demanding services, with configurations such as double mechanical seals used on certain duties where additional containment or reliability is required. We can guide you on what features make sense based on the product, operating conditions, and site requirements.

To specify the right fuel transfer pump for a New Zealand site, we typically need the fuel type, required flow rate, temperature, and viscosity, along with suction conditions such as flooded suction or suction lift.

Once we have those details, we can confirm the most suitable pump type and configuration for your application – including options for heavier fuels where viscosity is higher.