Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

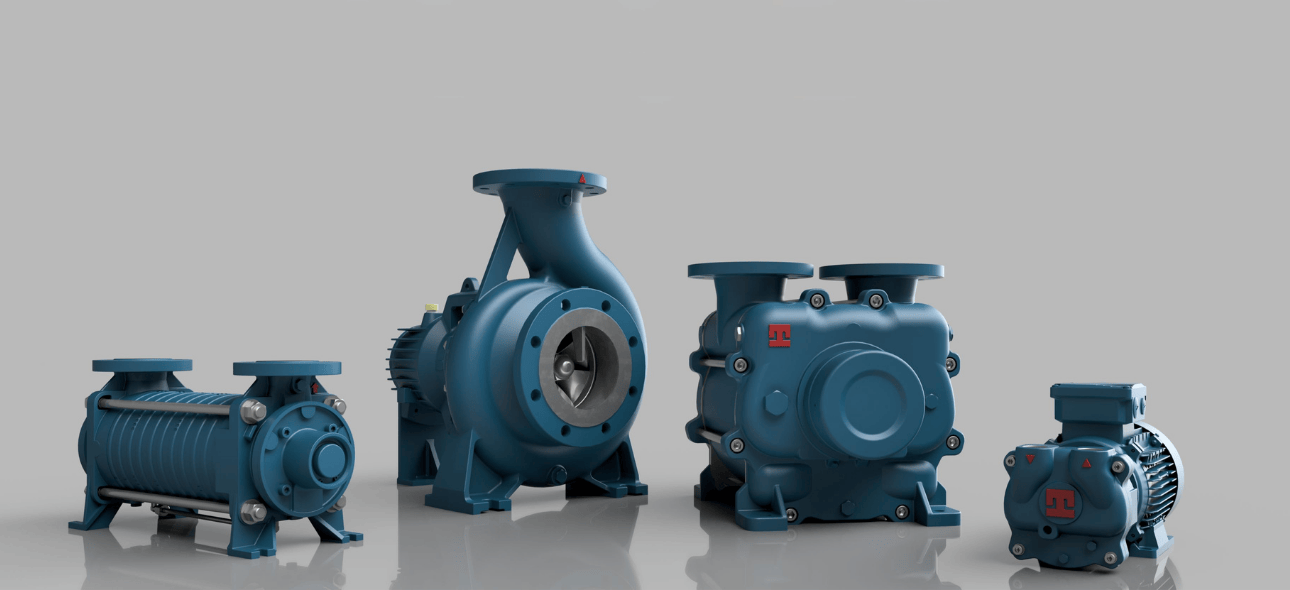

Industrial Side Channel Pumps

Low flow, high pressure solutions

Engineering Excellence

Pompe Travaini is a trusted manufacturer of high-quality vacuum pumps and liquid ring pumps, known for their reliability, energy efficiency, and advanced engineering. - Liquid Ring Vacuum pumps - Centrifugal pumps - Multi-stage and self-priming - Vacuum skids - Blowers, exhausters and boosters

Pumps for challenging industrial applications.

Specialists in industrial liquid-, gas- and vapour-handling, SIHI pumps are well-regarded for dependability in challenging industrial applications. - Side channel - Liquid ring pumps - Vacuum pumps - Compressors

Overview of our Industrial Side Channel Pumps

High duty self-priming segmental pumps designed for chemical and hazardous liquids (X) and liquified gases.

- Max flow: 35m3.hr

- Max head: 348m

- Nominal pressure: PN40

- Materials: cast iron, ductile iron, stainless steel, alloy

Medium duty, self-priming segmental pumps suited to shipyard use, dissolved air flotation and CIP.

- Max flow: 35.5m3/hr

- Max head: 144m

- Nominal Pressure: PN16 PN25X

- Materials: cast iron, bronze, stainless steel, alloy

Self-priming pumps used for clean and grey water, wells and irrigation and fuel transfer.

- Max flow: 7.5m3/hr

- Max head: 100m

- Nominal Pressure: PN10

- Materials: cast iron, bronze

Handle liquified gases, condensates, chemical and hazardous liquids in unfavourable suction conditions.

- Max flow: 35.5m3/hr

- Max head: 354m

- Nominal Pressure: PN40

- Materials: cast iron, ductile iron, stainless steel, alloy

Multistage self-priming centrifugal pumps. Suitable for gases, clean liquids and corrosives hot or cold.

- Max. flow: 70m3/hr

- Max pressure: 40 bar

- Max. lift: 8.5 mwc

Multistage self-priming centrifugal pumps suitable for gases, clean liquids and corrosives hot or cold.

- Max flow: 7.5m3/hr

- Max pressure: 150m

- Lift: 7m

- Max Temp: 120°C

Prime Fluid Management supplies genuine parts for our pump brands, holding stock of common wear parts in New Zealand.

- Genuine parts

- Stock held in NZ

- Maintenance advice

- Servicing on request

Have Questions? Need help to spec? Speak with one of our Industrial Specialists

In the field

Here are some examples of our solutions being used.

Read Sludge & Slurry Articles

They brought their mechanics, they didn't just dump it and leave….couldn't have done it without them to be honest

This sort of unique system you set up is what sets you apart from others in the Market

I had an amazing experience with Prime Pump at the Transmission Gully ... will recommend you guys anytime and anywhere.

You guys had our backs from the get-go and stood beside us and persevered.

We called for a different type of solution…... We were pretty happy with what's been delivered

Prime supplied us with the best solution for hire and the instant availability was what we needed… We certainly will be using them in the future

Make an enquiry

FAQ

At Prime Fluid Management, we understand that every fluid management challenge brings unique considerations. Here, you’ll find clear, practical answers and expert guidance to help you maximise uptime, achieve regulatory compliance, extend equipment life, and implement the most effective solution for your site.

A slurry pump is designed to move mixtures of liquid and solid particles where the liquid component helps the material flow. It is built with abrasion and corrosion resistant materials and a robust design to handle the wear from suspended solids.

A sludge pump is designed to handle much thicker and stickier material known as sludge which has a higher solid content. These pumps often use positive displacement or slow moving mechanisms to avoid clogging and manage dense viscous fluids.