Process Pumps for Slurry & Sludge Transfer

For transferring abrasive slurry and sludge in NZ quarries and mines - where reliability, serviceability,and uptime are critical to safe, efficient operations.

- Home

- Solutions

- Sludge & Slurry

- Process Pumps

Ergonomic Pumps for Safer Slurry Transfer

Process pumps are essential for moving abrasive slurry and sludge within quarry and mine processing plants. Whether transferring tailings, mineral concentrate, or waste slurry, these pumps must perform reliably under high solids loading, corrosive conditions, and continuous operation. Our range of process pumps is selected not only for durability and long-term cost efficiency, but for ease of maintenance and safety - supporting safe, uninterrupted plant operations.

Our range of process pumps is selected not only for durability and long-term cost efficiency, but for ease of maintenance and safety - supporting safe, uninterrupted plant operations.

Applications in Quarrying and Mining Plants

Process pumps are used in:

- Tailings transfer: Moving processed waste slurry to containment or disposal.

- Ore and concentrate transport: Pumping mineral-rich slurry between stages of processing.

- Waste slurry removal: Clearing residual sludge from thickeners, clarifiers, or settling tanks.

- Reagent and chemical slurry handling: Transferring corrosive or abrasive mixtures used in processing.

These applications demand pumps that can handle high solids content, variable flow rates, and aggressive media without frequent breakdowns.

Pump Types for Slurry Transfer

We supply heavy-duty centrifugal slurry pumps designed for use in processing plants:

- Horizontal process pumps: Ideal for consistent flow in mill discharge, tailings, and slurry transport lines.

- Vertical process pumps: Used in sumps and tanks where space is limited. Cantilever shaft design eliminates submerged bearings and seals, reducing maintenance.

- Material options: High-chrome alloys and elastomers available.

- Flexible configurations: Modular motor mounts and impeller designs.

Why SlurryPro Pumps?

SlurryPro pumps are engineered for abrasive slurry transfer in processing environments. Their modular design and field-serviceable components make them a practical choice.

- Sliding base with hydraulic ram: Enables single-person maintenance, reducing downtime by up to 50%.

- Automatic greasers: Extend asset life and reduce manual servicing.

- Mechanical seals: Minimise leakage and wear, lowering water usage and repair frequency.

- Freeze Prevention Technology (FPT): Protects pump integrity during cold starts.

SlurryPro offers both horizontal and vertical pumps in a wide range of sizes, with rapid quoting and delivery available.

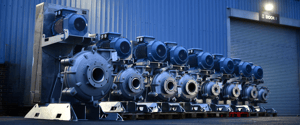

Overview of our Process Pumps for Slurry & Sludge Transfer

A rugged and cost-effective solution the Proril Stormy series feature high chrome impellers, agitators and wear plates to withstand tough slurry transportation.

- Size: 75mm – 200mm (3” – 8”)

- Max flow: 110L/s

- Max head: 30mwc

- Max solids: 40mm

The optional sliding base enables safer, faster maintenance, reducing downtime by up to 50%.

- Award-winning hydraulic ram design

- One-person wet-end access

- No lifting gear required

Explore the SlurryPro brand page

FAQ:

Selecting the correct pump depends on:

Slurry type: settling vs. non-settling, particle size, and abrasiveness.

Flow and head requirements: Distance and elevation of transfer.

Plant layout and constraints: Space, access, and integration with existing systems.

Our team can assist with pump sizing, configuration, and performance optimisation.