Pump Types

Auto Prime

Air-operated

Concrete Washdown

Dredge Pumps - Dewatering

Dredge Pumps - Sludge & Slurry

Dredges

Flexi, Trash & Diaphragm

High Head Pumps

Handy-sized Pumps

Lamella Settling Tanks

Peristaltic

pH Correction

Piston Pumps

PTO (auto prime)

Centrifugal

Primary Sludge

Progressive Cavity

Shore-mounted

Stirrers

Submersibles

Proportional Dosing

Settling Tanks & Bag

Submersibles - Drainage

Submersibles - Slurry & Sludge

Stirrers - WWTP

Trash, Flexi & Diaphragm

Water Quality Monitoring

Wellpointing

Chemicals

Food Processing

Fuels & Oils

Hot Oil

Hot Water

Hygienic

Marine

Solids Handling Pumps

Vacuum & Blowing

Viscous Fluids Pumps

Wastewater

Comprehensive water treatment and monitoring solutions

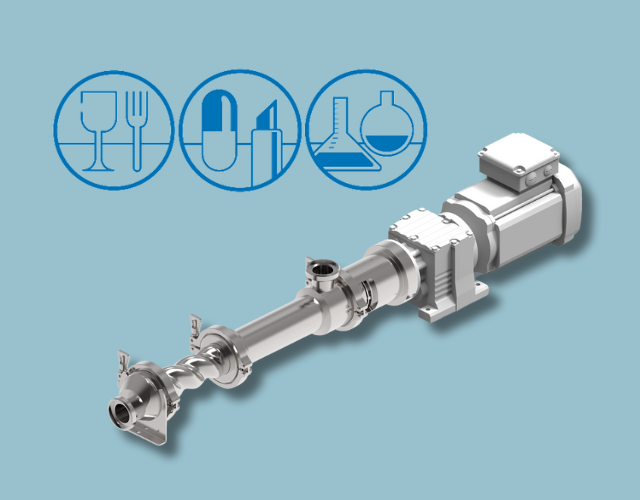

Food Processing Pumps

Hygiene, efficiency, performance

Pioneering user-friendly design

German pump manufacturer Wangen Pumps is renowned for its ultra-efficient pumping solutions. They supply a range of medium-specific pumps that are gentle on the product and reliable.

Their promise? The optimum pumping solution for every medium.

- Low pulsation pumping, no matter the media

- Ease of cleaning and maintenance (CIP and SIP)

- Exacting hygiene standards (EHEDG certification)

- Reliable access to spare parts & service

Conveying highly viscous media

Wangen MX Series pumps provides uniform metering, low-pulsation transfer of aqueous to highly viscous media. Their cassette design ensures minimal dead space and simplifies maintenance and repair, making them the perfect food processing pumps.

- precise, low pulsation flow

- available in stationery or mobile units with short assembly length

- MX-F is otimsied for emptying drums and vessels containing highly viscous mediums

Overview of our Food Processing Pumps

Wangen's KL-S, KB-S and KB22S self-priming PC pumps convey high viscous media up to 200,000mPA-s with or without solids. The KB22S is designed specifically for dosing.

- Max Flow: 560 m3/hr

- Max Pressure: 48 bar

- Materials: S/steel, cast iron

Horizontal single-stage pumps for mineral or synthetic heat transfer oils up to 350°C. Suitable for positive and negative suction pressure installations, they feature a back pull-out design for maintenance without disturbing pipework.

- Max temp: 350°C

- Max flow: 1000 m³/h

- Max head: 95 m

Varisco V-Series volumetric internal gear positive displacement rotary pumps manage clean fluids with high viscosity where chemical-physical alteration must be avoided.

- Max capacity: 240m3/h

- Max pressure: 16 bar

- Ports: 40-200mm

- Std Set ups: bare shaft, base+joint, vertical

TCD-Series single-stage centrifugal pumps will handle thermal fluids up to 365 degrees without additional cooling systems. TCD/SP Series pumps are specifically designed for vegetable oils.

- Max flow: 450 m3/hr

- Max head: 150m

- Max temp: 365 degrees

- Material Options: Ductile Iron & AISI 316 S/Steel

Horizontal single stage pumps for hot water up to 207°C, with double heat barrier used primarily for hot water circulation in closed pipe and vessel systems.

- Max flow: 600m3/hr

- Max head: 90m

- Max temp: 207°C

- Casing Pressure: PN25

Volute pumps for hot water up to 180°C, with standard uncooled mechanical seal, and internal separation.

- Max flow: 600m3/hr

- Max head: 95m

- Max temp: 180°C

- Casing Pressure: PN16

Volute pumps for hot water up to 230°C with standard uncooled mechanical seal, internal separation.

- Max flow: 600m3/hr

- Max head: 90m

- Max temp: 230°C

- Casing Pressure: PN40

The Hyline Series by Wangen features flexible and maintenance-free joints, and sedimentation-free design. Convey or dose food and beverages, cosmetics and pharmaceuticals.

- Max flow: 7m3/hr

- Max pressure: 20 bar

- Max solids: 26mm

Wangen’s KB-SL, KL-SL and KL-RF hygienic progressive cavity pumps are tailored to convey low to very high viscosity media.

- Max flow: 150m3/hr

- Max temp.: 140°C

- Max pressure: 48 bar

- Max viscosity: 200,000 mPa-s

Available as a mobile or stationery unit, the MX-series hygienic progressive cavity pump offers differential pressure up to 80 bar.

- Max flow: 100m3/hr

- Max pressure: 80 bar

- CIP/SIP cleaning possible

Wangen Twin Screw pumps ensure smooth, gentle pumping of viscous, abrasive or shear-sensitive fluids, with CIP/SIP cleaning and minimal downtime.

- Max flow: 200 m3/hr

- Max pressure: 30 bar

- Max solids: 40mm

A patented feeder unit for the Wangen Twin Screw pump. Conveys highly viscous, non-flowable media with variable hopper length.

- Max flow: 10 m3/hr

- Max temp: 90°C

- Max viscosity: 3,000,000 mPa-s

The Varisco V CHOCO series internal positive displacement pumps are tailored specifically to chocolate manufacture.

- Pumps non-acidic food liquids, >pH4.5

- No fluid crushing

- No sugar crystallization

- Guaranteed temperature stability

Single stage centrifugal pumps with closed impeller. Pompe Travaini TCH Series pumps have high hydraulic efficiency and low NPSH requirements.

- Max flow: 500 m3/hr

- Max pressure: 16bar

- Max Temp: 280°C

Prime Fluid Management supplies genuine parts for our pump brands, holding stock of common wear parts in New Zealand.

- Genuine parts

- Stock held in NZ

- Maintenance advice

- Servicing on request

In the field

Here are some examples of our solutions being used.

Read Dewatering, Bypass & Sewage articles

See other Dewatering, Bypass & Sewage Pumps

They brought their mechanics, they didn't just dump it and leave….couldn't have done it without them to be honest

This sort of unique system you set up is what sets you apart from others in the Market

I had an amazing experience with Prime Pump at the Transmission Gully ... will recommend you guys anytime and anywhere.

You guys had our backs from the get-go and stood beside us and persevered.

We called for a different type of solution…... We were pretty happy with what's been delivered

Prime supplied us with the best solution for hire and the instant availability was what we needed… We certainly will be using them in the future

Make an enquiry

FAQ

At Prime Fluid Management, we understand that every fluid management challenge brings unique considerations. Here, you’ll find clear, practical answers and expert guidance to help you maximise uptime, achieve regulatory compliance, extend equipment life, and implement the most effective solution for your site.

On a lot of drawings and pump schedules, dry-prime pump or dry-prime dewatering pump is used as shorthand for a surface pump that can handle air and doesn’t need manual priming. In practice, the auto-prime units that Prime Fluid supplies are vacuum-assisted pumps with a dedicated priming system, so they meet the intent of most “dry prime” specs while giving you a modern, quieter and more efficient package.

Auto-prime units are usually the better option when the pump has to sit above the water, suction conditions might change, or you expect a lot of air to enter the line during setup and operation. A self-priming dewatering pump or submersible can still be the right choice on simpler, more static jobs, and Prime can talk you through which option will be more reliable and cost-effective for your site.

Yes – Prime can supply auto-prime packages as diesel dewatering pump sets or electric sets, depending on what power you have available and how the system will run. With the right control panel and level sensors, those same units can be configured as an automated pump or “auto water pump” that starts and stops itself, which is helpful on remote or 24/7 sites where you don’t want someone constantly watching the pump.

Auto-prime units are a good fit for temporary flood control pumps because they can be moved quickly, cope with long suction and discharge lines, and re-prime themselves as water levels change. Prime Fluid can set up high-flow Auto-prime Pump solutions for New Zealand councils and contractors that form part of a wider flood or stormwater contingency plan.

To match an Auto-Prime Pump New Zealand job, one of our sales engineers will usually ask for your required flow, total dynamic head, suction depth, discharge route, expected solids size and how long the pump needs to run. If your documents mention terms like autoprime dewatering pumps, auto vacuum pump or use a generic “dry prime” note, sending those details through with a simple sketch of the setup helps the team recommend the most suitable package for your project.